Resolution

When it comes to 3Dprinting there is a lot of confusion about resolution. It is important in different contexts, so I hope this post can help to demystify it.

Scanning is a method to capture geometry from real world objects to create a digital model. Here is a scan of my head, using a structured light scanner attached to an iPhone. On the right hand side, you can see a triangulated mesh of polygons. This mesh is the 3D model. Notice the lack of details in the face, especially the eyes. the Mesh is composed of 53,000 polygons.

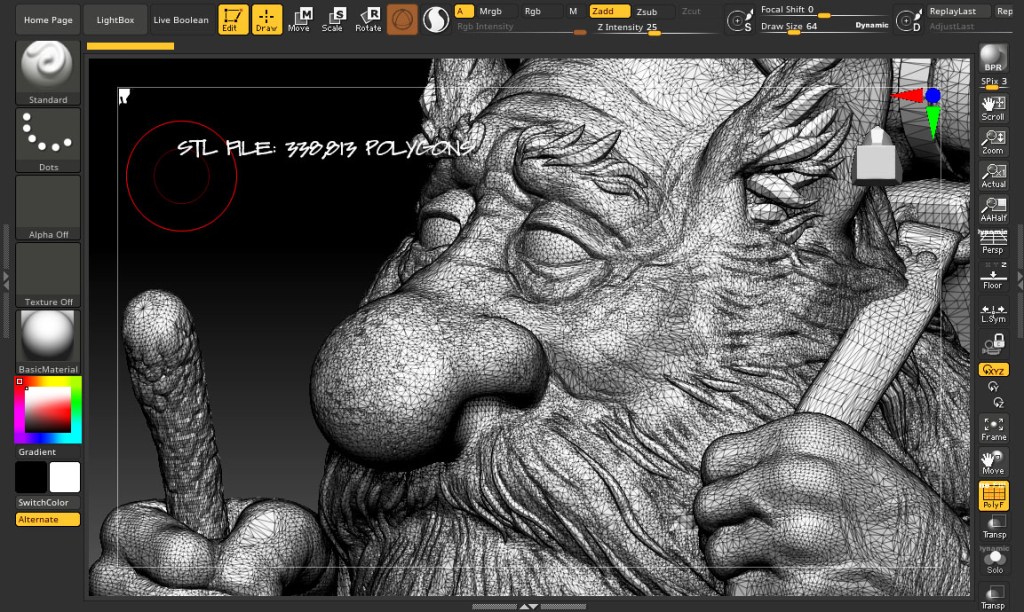

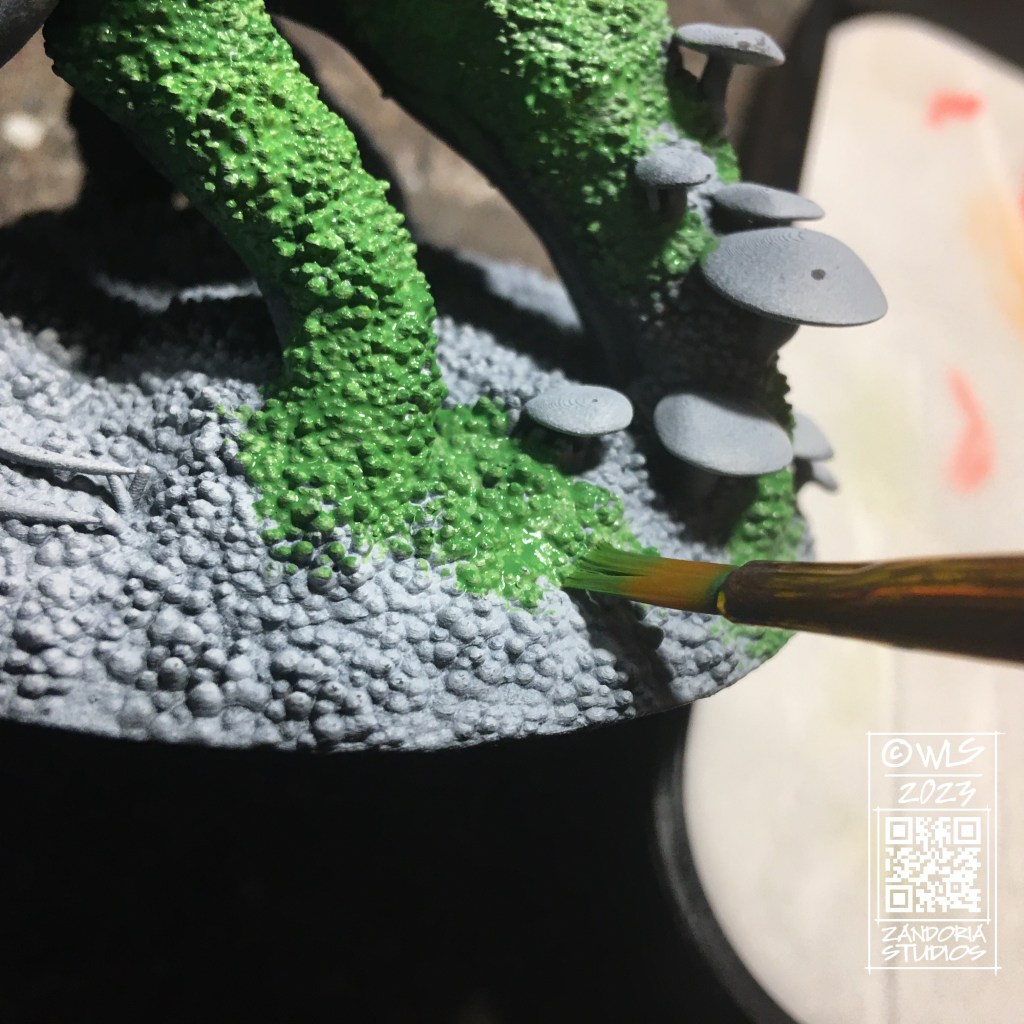

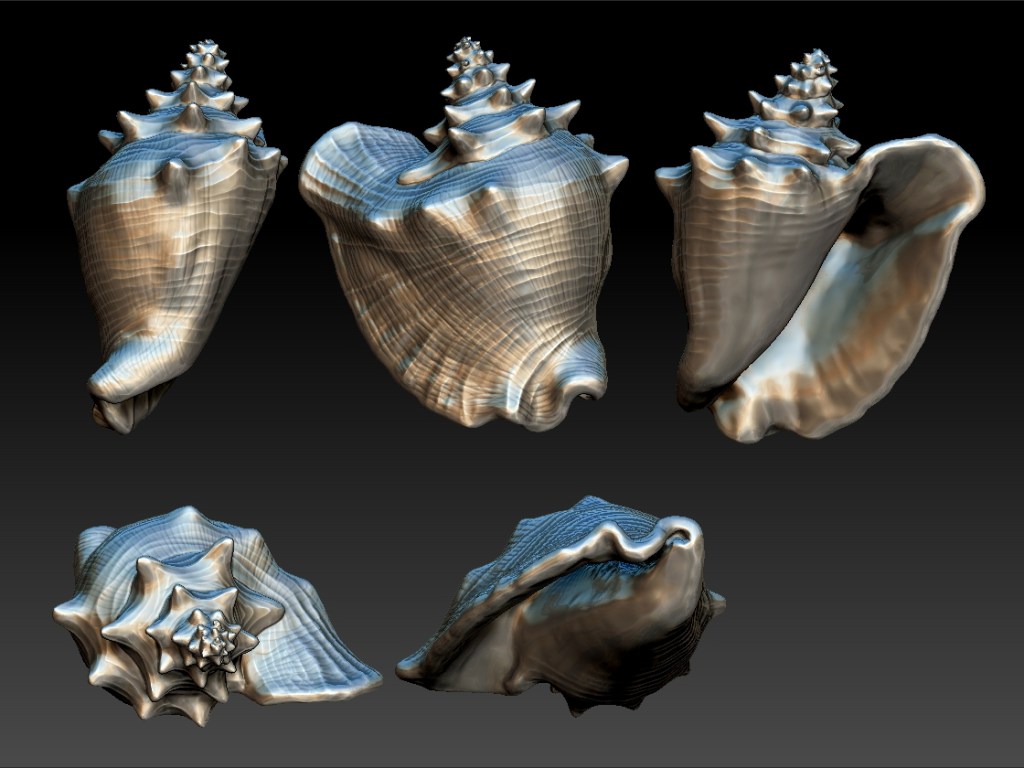

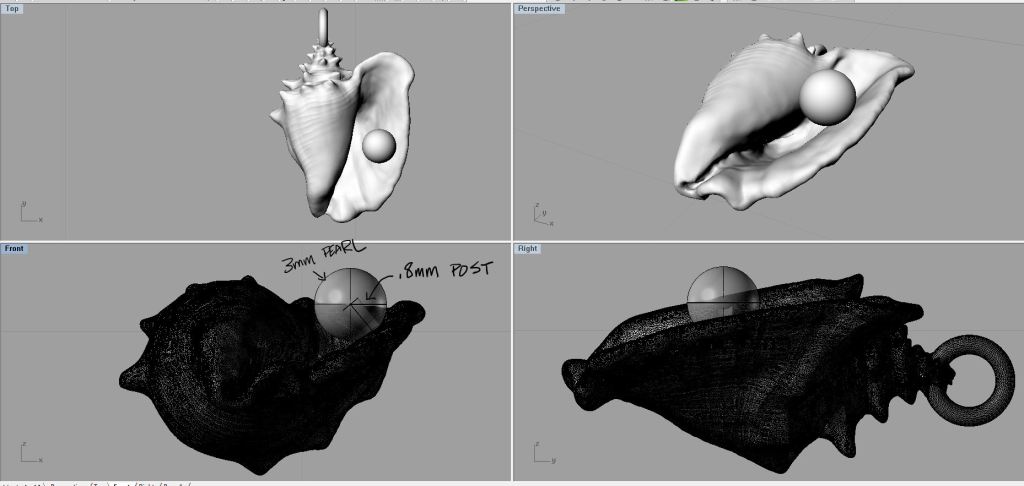

This Gonk Gnome is a digitally sculpted model for 3Dprinting. The STL file is what is used by the slicer to output the instructions to the printer. This polygon mesh is 338,813 polygons. The resolution is higher than the scan–meaning that the triangles are smaller, and denser.

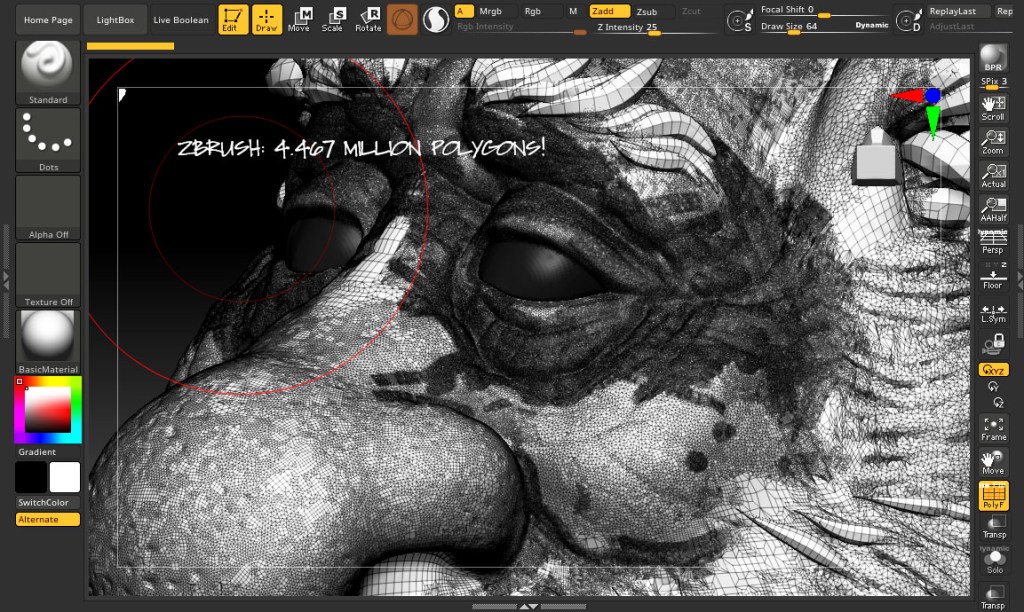

In ZBrush, the original mesh that is the actual digital sculpture, is over 4 MILLION polygons! If you notice those darker gray areas around the eyes, those are even denser polygons than the rest of the mesh. Sculpting digitally, you can zoom in and add more detail, and resolution (to the limits of the computers memory).

The reason that the STL file is less polygons is that it is decimated from the higher resolution mesh. A 3Dprinter slicer will have a hard time with a mesh over 1 million polygons, so you have to balance the amount of detail you can reproduce with those constraints and the intended size that you will print.

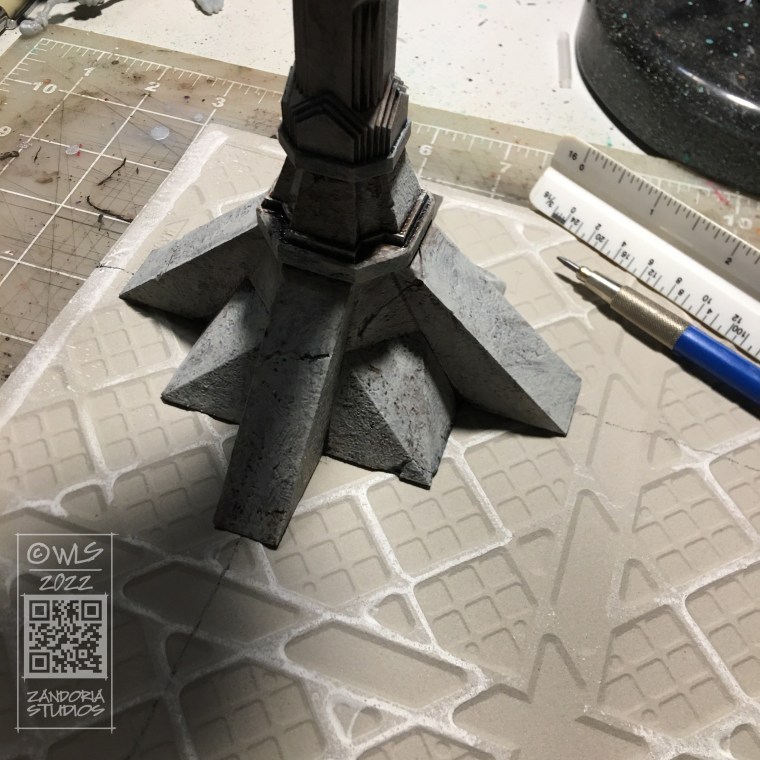

Here is a picture of that model 3Dprinted in resin. the layer thickness for a resin printer is .05mm (about the thickness of a human hair), so you need a magnifying glass to be able to see the layer lines…

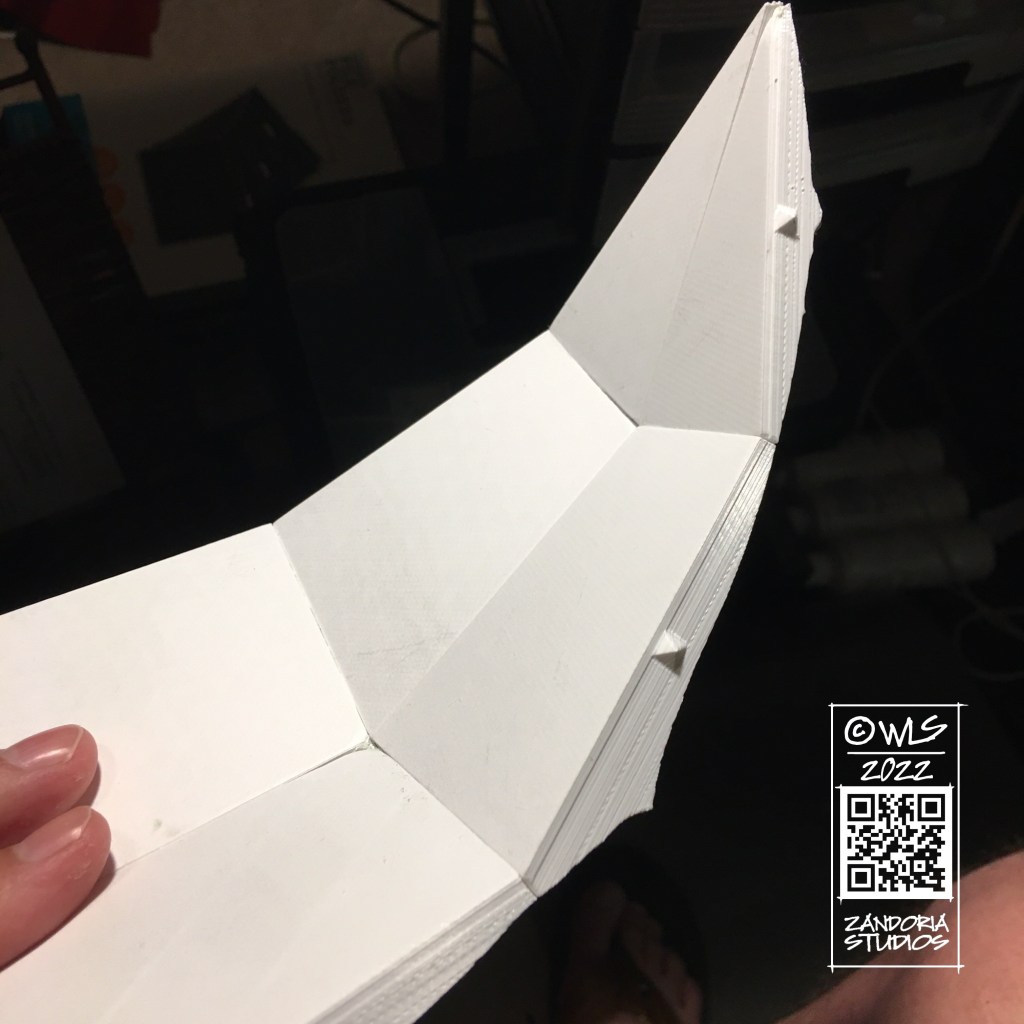

3Dprinters are advertised with 2K, 4K, 8K, 12K (even higher has been announced), which is referring to how dense the pixels in the LCD screen are. This can get confusing, because a small screen size that is 2K might have the same density of pixels as a larger screen that is 4K. So, in choosing between the different resolutions offered in 3Dprinters, it is important to choose a size that fits your needs, then worry about how much resolution in in that LCD screen. Ideally, the XY resolution (the LCD screen) and the Z (the layer height) should be the same.

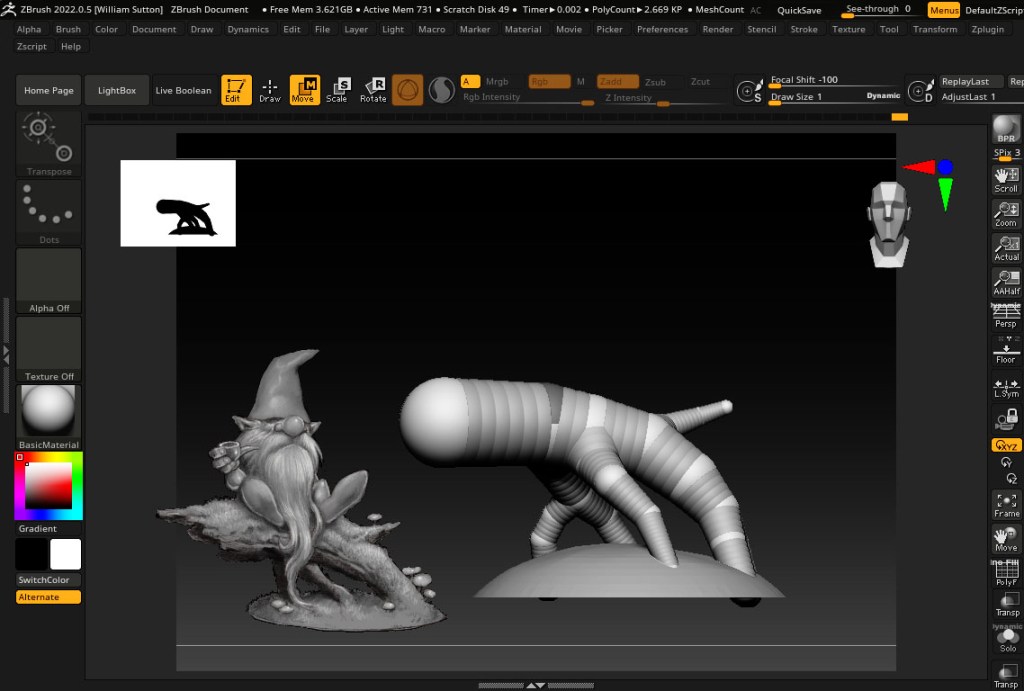

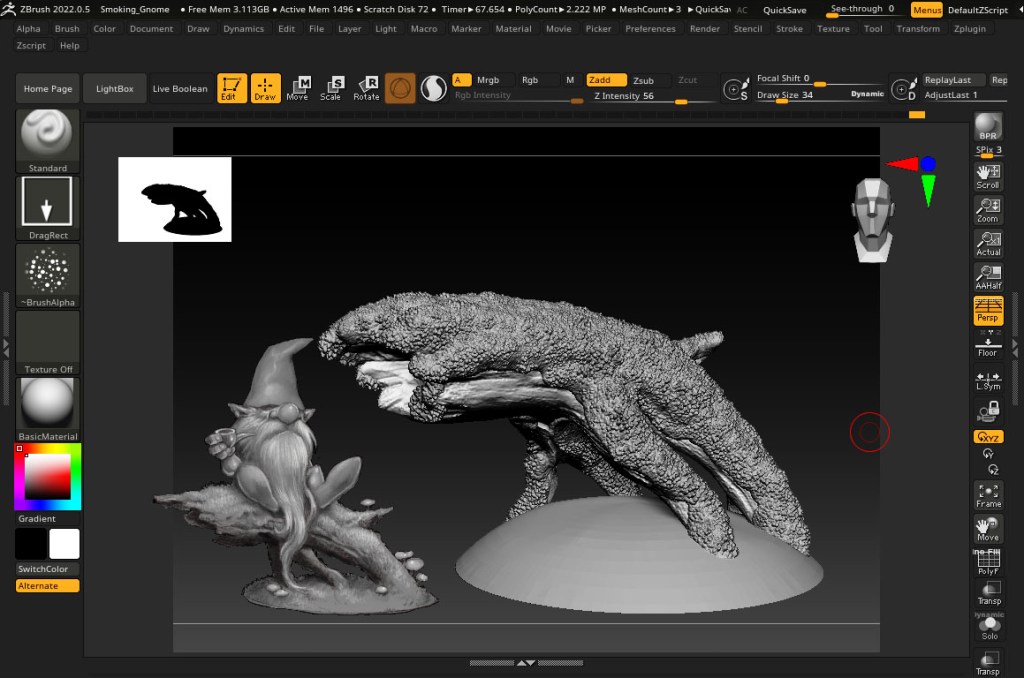

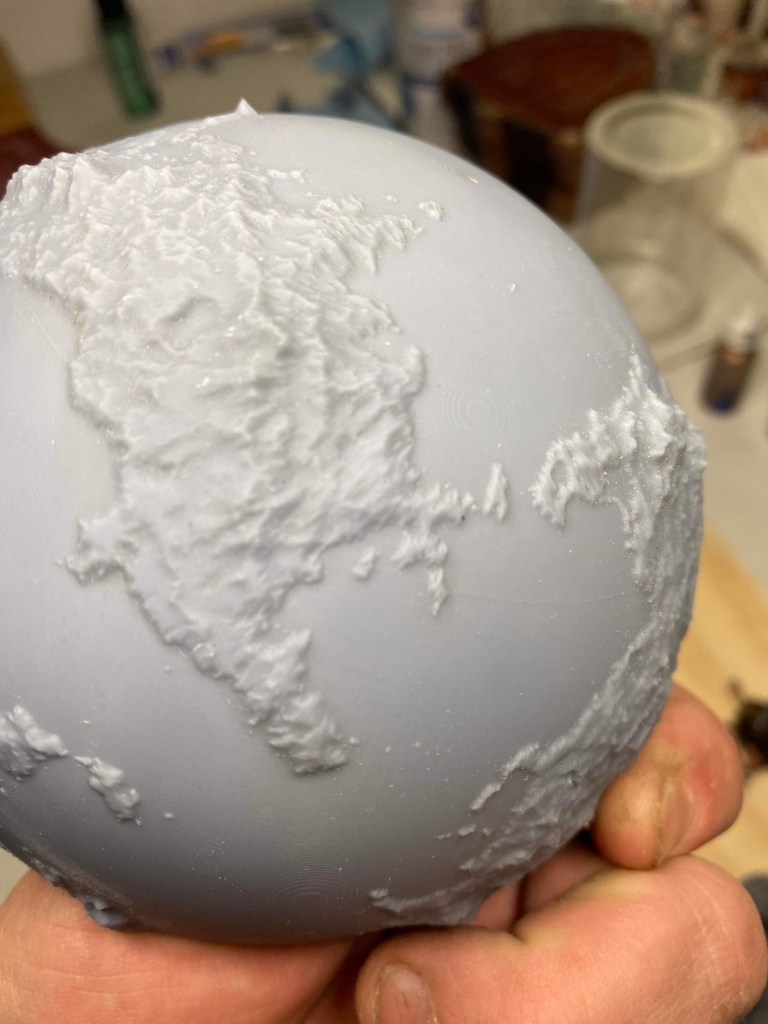

This Gonk adventurer is the same model, but at different scales. the density of the polygons is high enough that even when printed larger the detail is there. If the gonk was printed even smaller than a D&D miniature, you will start to lose the finer details as the size of the triangles of the polygon mesh become smaller than the XYZ resolution of the printer. If you printed larger than a figurine, like a 4′ or taller statue, the size of the triangles of the polygon mesh would become visible.

Because there can be so much variation in size for the 3Dprints, I usually will decimate the mesh to between 300,000 and 600,000 polygons. That provides enough resolution to the polygon mesh, so that the detail is there even if you need some 2′ Guardin’ Gnomes.

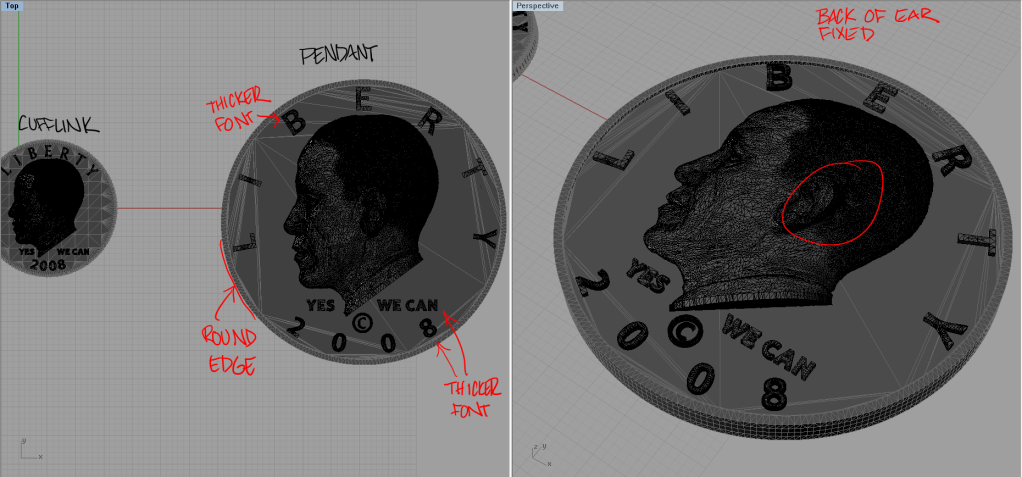

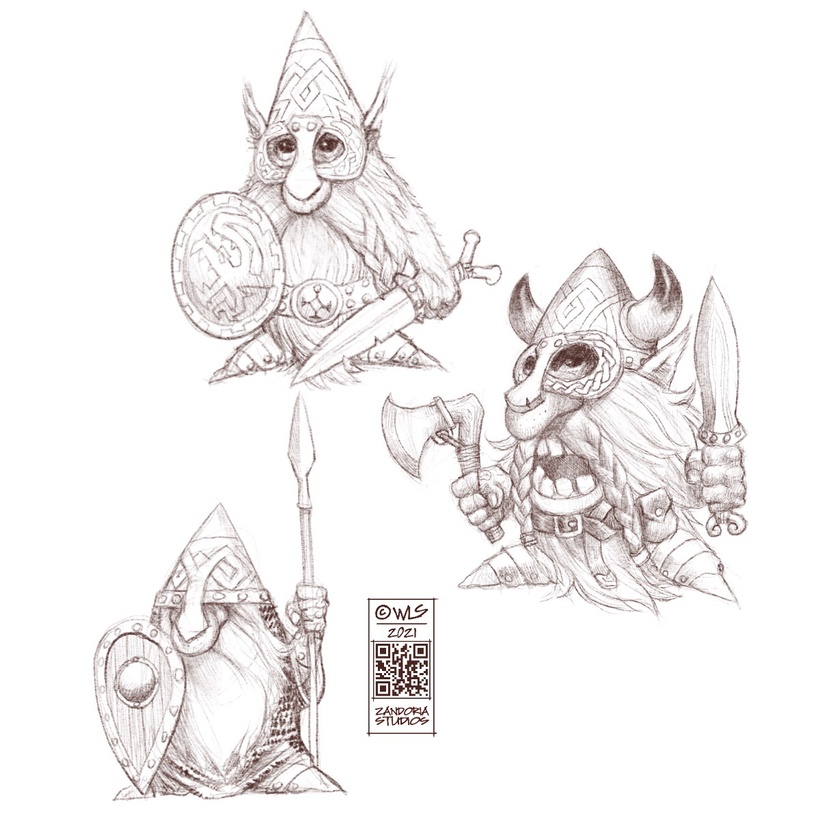

So now I’m thinking about creating a series of miniatures myself and offering for sale… What about a series of 54mm miniatures inspired by my Dark Lead sketchbook?

So now I’m thinking about creating a series of miniatures myself and offering for sale… What about a series of 54mm miniatures inspired by my Dark Lead sketchbook?